Whether you’re designing the electrical system for a new building (or campus), adding an electrical system to an existing building, or designing in a new production line (or system), an electronic power supply or piece of equipment into an existing building, having PBE review your design for PQ performance will help you & your customer reduce the risk of malfunctions, damage & failures. Architects & Engineers should design electrical systems that can minimize & control electrical instabilities when utility disturbances, thunderstorms & customer load operations / switching occur.

For Architectural & Engineering Firms, PBE’s review of your building electrical design will result in design improvements that will not only “harden” your system to unpredictable electrical threats but also increase compatibility between the grid, your system & the customers’ equipment.

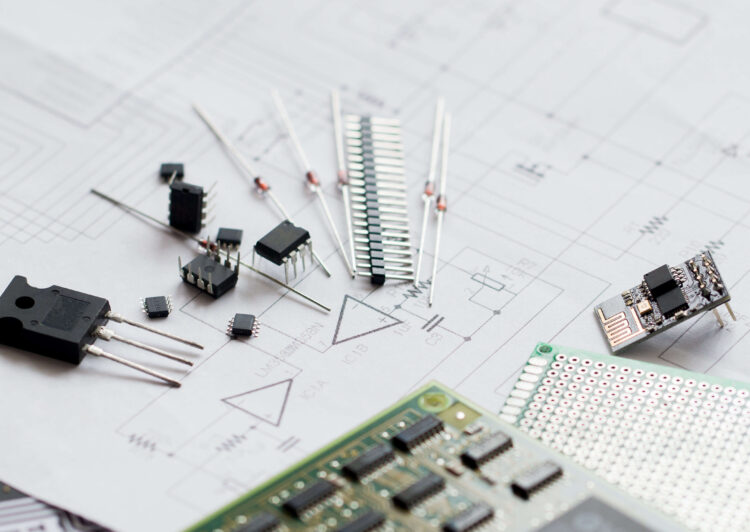

For Equipment Manufacturers, Engineers who design electronic power supplies (or products that contain them) should incorporate components that will protect the design from external (& internal) electrical threats. They should also ensure that operating the intended load from the power supply will not cause disturbances to be injected back into the building electrical system.

PBE’s review of your electronic power supply design will result in design improvements that will not only “harden” your supply to unpredictable electrical threats but also increase compatibility between the building electrical system & the surrounding electrical environment & your supply as well as reduce the risk of interactions between your supply & other electronic loads.

Customers don’t have time for facility engineering reworks or downed production lines while changes are made to electrical infrastructures that could have been done during the design phase. Some commercial and industrial facilities plan to operate more electrical and electronic equipment than others, or equipment known to be more disturbance-causing or sensitive than other equipment. Some facilities will be powered from utility feeders with more energetic power quality disturbances than other feeders. Some facilities will be located adjacent to transmission towers. Some facilities will be built on soil with compromised conductivity, leaving grounding performance to be challenged. Some facilities will end up allowing high harmonic currents to flow despite on-board filtering. Some facilities will operate equipment that generates more disturbances. Some facilities will use radio-frequency (RF) generating equipment. No two facilities are alike when it comes to the activities they’ll be doing and the usage of their electrical infrastructure.

Having PBE expert power quality engineers conduct a thorough design review of the electrical infrastructures and planned loads in a facility is time and money very worthwhile spent. In all cases this activity saves thousands, if not millions, of dollars in lost production time, downed equipment, equipment repair costs and product re-work costs. PBE developed a process for reviewing facility electrical systems that improves the power quality performance of the system & the equipment it has to power & operate. PBE also provides justification documentation for changes that do increase costs, so that customers clearly understand what the power quality improvements they are receiving for their investment. PBE can provide a detailed proposal for a facility design review, depending on the facility type and other factors that impact the power quality performance at a facility. Topics include wiring and grounding, location and type of permanent power quality monitoring, modeling and simulation of electrical conditions including faults, harmonics, lightning protection, arc flash protection and power quality mitigation of common every day electrical disturbances to name a few.

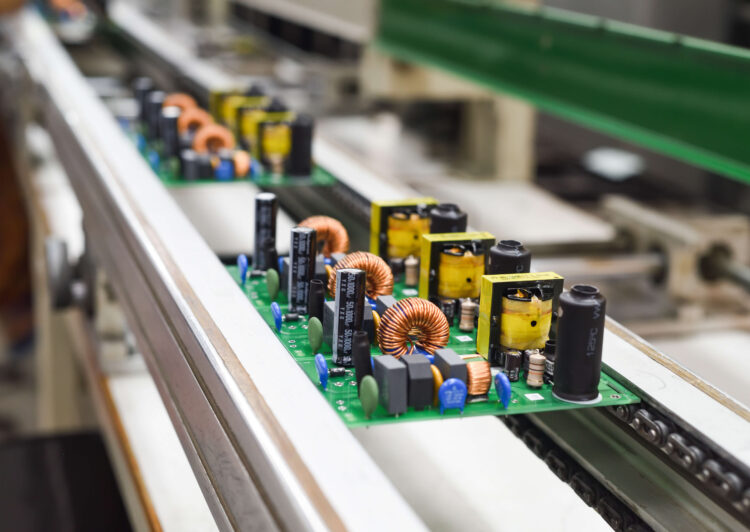

Every piece of electronic equipment requires an electronic power supply to interface the equipment to an AC or DC power source. Most end-use equipment uses an AC power source originating from the utility grid. Although the source is from the grid, the equipment is interfaced to a feeder or branch circuit on the customer’s electrical system.

Wiring & grounding (W&G) problems in the customer’s electrical system can add or magnify electrical disturbances originating from the grid. W&G problems can also create undesirable electrical conditions that place equipment & safety in jeopardy. Knowing that most PQ problems involving customer equipment are caused by W&G problems in the customer’s electrical system, equipment manufacturers must be concerned with what their products must endure in common everyday electrical environments.

PBE has extensive experience in applying real-world PQ emissions & immunity tests to end-use products. Our process takes the tests defined by industry standards & adds a level of real-world exposure to each test. This process helps to identify the weak links in manufacturer’s designs. All of the test procedures & results are numerically & visually recorded. PBE uses real-world electrical disturbances (low- & high-frequency) which are injected / applied to the product. PBE also applies tests to the product that recreate real-world electrical conditions commonly found in customer facilities that PBE has identified to have caused problems with electronic equipment.

Part of PBE’s expertise in this area of PQ includes identifying the changes that need to be made to electronic circuitry / product designs needed to improve PQ performance, so products have a lower risk of malfunction, damage & failure in the real-world electrical environments of customer facilities.

Want to learn more about PQ & keep up with new PQ problems facing customer facilities, plus much more? Subscribe to one of PBE Engineers’ newsletters that’s free!